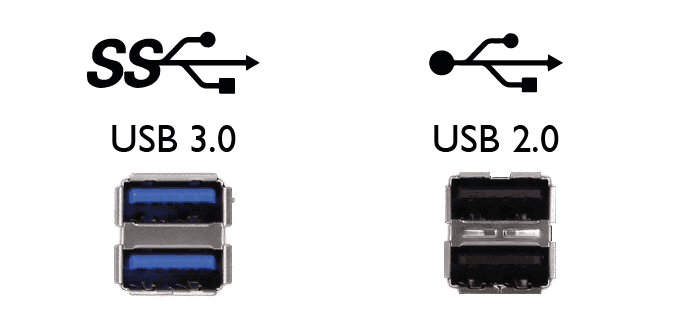

USB 3.0 vs 2.0: Which One is Best for Optimized Performance and Cost-Effectiveness?

Finding a balance between performance and cost when selecting USB 3.0 and 2.0 for industrial projects is essential. Since its debut in 1996, USB technology has advanced greatly; more specifically USB 3.1 Gen 1 now offers much faster transfer speeds than its predecessor USB 2.0; but does that necessarily equate to opting for this version over another? In this article we’ll outline key differences between USB 3.0 and 2.0 while providing recommendations of CPUs compatible with such projects.

USB 3.0 vs 2.0 Comparison Table

Here’s a handy comparison table between USB 2.0 and 3.0:

| Feature | USB 2.0 | USB 3.0 |

|---|---|---|

| Release Date | April 2000 | November 2008 |

| Speed | High Speed or HS, 480 Mbps | 10 times faster than USB 2.0, Super Speed or SS, 4.8 Gbps 👑 |

| Data Throughput | Adequate for basic tasks, limited to 480 Mbps. Not ideal for high-bandwidth applications. | Significantly higher, up to 4.8 Gbps. Ideal for applications that require high-speed data transfer. 👑 |

| Signaling Method | Polling Mechanism (Half Duplex) | Asynchronous Mechanism (Full Duplex) 👑 |

| Error Handling | Limited error correction capabilities, may require retransmission of data packets. | Advanced error correction, providing more reliable data transfer in industrial settings. 👑 |

| Compatibility | Mostly backward-compatible with USB 1.1; limited forward compatibility. 👑 | Backward-compatible with USB 2.0 and earlier, ensuring easier integration into existing systems. |

| Latency | Higher latency, which might be a bottleneck in real-time applications. | Lower latency due to asynchronous signaling, better suited for real-time industrial applications. 👑 |

| Security Features | Basic security features, may require external solutions for secure data transfer. | Improved security features, including encryption and authentication, better suited for secure industrial applications. 👑 |

| Power Management | Up to 500 mA; less efficient in energy management. | Up to 900 mA; more efficient power management features suitable for energy-sensitive industrial applications. 👑 |

| Price | Generally less expensive 👑 | Generally more expensive |

| Max Cable Length | 5 meters 👑 | 3 meters |

| Number of Wires | 4 | 9 |

| Standard-A Connectors | Black | Blue |

| Standard-B Connectors | Smaller in size | Extra space for more wires |

When to Use USB 2.0

USB 2.0 remains widely utilized across numerous industrial applications; here are a few instances when this technology might be the better choice:

- Low-bandwidth devices: If your device requires low-bandwidth data transfer, such as keyboard or mouse use, USB 2.0 would likely suffice. As these don’t necessitate high-speed transfer rates, using them could prove more cost-effective.

- Cost-sensitive applications: USB 2.0 products tend to be more cost-effective for industrial applications where cost is a primary consideration, making USB 2.0 products the more suitable option.

- Longer cable length: USB 2.0 can accommodate cable lengths up to 5 meters while USB 3.0 is limited to three meters, so if your industrial application requires longer cable runs then USB 2.0 would likely be the better choice.

When to Use USB 3.0

USB 3.0 offers faster transfer speeds and lower power usage than previous generations of USB, making it ideal for industrial applications requiring high-bandwidth data transfers. Below are some use cases of USB 3.0 in industrial settings:

- High-bandwidth devices: USB 3.0 is an ideal choice for high-bandwidth devices like external hard drives that need fast data transfer speeds, as well as industrial applications in which this speed of data transmission is essential.

- Wi-Fi or Bluetooth dongles: Industrial applications that require wireless connectivity such as Wi-Fi or Bluetooth benefit from USB 3.0 dongles as they offer faster data transfer speeds than their predecessor, USB 2.0 dongles. This feature is particularly important in real-time data applications such as industrial automation.

- 4K video playback: USB 3.0 provides ample bandwidth to support the transfer of 4K video content. When used for industrial applications that necessitate 4K video playback, USB 3.0 should be the go-to solution.

As well as taking into account your intended application and devices being used, when selecting between USB 2.0 and 3.0 it’s also essential to consider CPU compatibility when making your decision. Some CPUs might not support USB 3.0 so it is vital that you double-check all specifications of your device to make sure that it will support that particular standard.

USB Compatibility and Supported CPUs:

| USB Compatibility | CPU Models |

|---|---|

| USB 3.0 | RK3588, RK3566, NXP i.MX8M Quad, NXP i.MX8M Plus, Nvidia Jetson NX2, Nvidia Jetson Nano |

| USB 2.0 | RK3368, RK3328, MediaTek Genio 500, MediaTek Genio 350, NXP i.MX8M Mini |

Check out our H/W Solution Guide by Chipsets for detailed information.

Conclusion

- Selecting USB 3.0 or 2.0 for industrial applications requires careful consideration of each project’s unique requirements and constraints.

- USB 3.0 provides faster transfer speeds and improved power efficiency, making it ideal for high-bandwidth data transfer applications such as 4K video playback or large file transfers.

- USB 3.0 offers backward compatibility as well as greater price premium than its counterpart, however the latter’s one drawback lies in being more expensive than its counterpart. Cost and desired cable length may be critical factors; therefore, USB 2.0 may be preferable.

- Not all CPU platforms and chipsets support USB 3.0, so it is essential to ensure compatibility when selecting a CPU for USB 3.0 applications.

- By understanding the key differences between USB 3.0 and 2.0 and considering the unique project requirements, industrial users can make more informed decisions that maximize system performance and cost-efficiency.

Empowering the Future of Smart Workplaces with LV-Tron’s Hardware

LV-Tron’s IoT hardware provides the foundation for the smart workplaces of the future. Learn how meeting room management, on-demand energy consumption, flexible working, and commitment to security can empower your business.

Expert Tips and Advises: Accelerate Your Room Booking Hardware Business by Knowing More About the End-Users

This article discusses the important factors to consider when choosing a panel PC for a room booking system, including performance, cost, customization, security, durability, manageability, and scalability. A reliable Design Manufacturing Service (DMS) partner is also crucial for technical support, customization, integration, and long-term maintenance. By choosing the right panel PC and DMS partner, facilities can enhance their conference room experience and meet the evolving demands of the market.

Building Automation Technologies starting with KNX

Compare the features and capabilities of popular building automation protocols such as KNX, BACnet, Zigbee, Z-Wave, and EnOcean and discover how they can enable smart buildings and workspaces.

Maximizing Performance and Minimizing Costs: How to Choose CPU Platforms for Industrial PCs

Maximizing Performance and Minimizing Costs: How to Choose CPU Platforms for Industrial PCs Comparing Popular Platforms: NXP, Rockchip, MediaTek, and Intel for Industrial PCsIntroduction When it comes to building industrial PCs, choosing the right CPU platform is...

Navigating the Challenges of IoT Projects: How an ODM Service Can Help Your Company Succeed

Building industrial PCs for IoT comes with unique challenges such as performance, security, scalability, integration, and maintenance. LV-Tron, with over 20 years of experience, can help you navigate these complexities and deliver optimized solutions.

AIoT for Smart Buildings, Workplaces, and Meetings

LV-Tron creates AI-powered IoT devices for smart buildings, workplaces, and meetings, using sensors and AI algorithms to adjust environments and improve productivity.

Enabling Sustainable and Green Workplaces, Buildings and Meeting Spaces

LV-Tron is a leading provider of design and manufacturing services that helps businesses create sustainable and green workplaces, buildings, and meeting spaces. By using technology to create sustainable spaces, businesses can reduce their environmental impact and improve efficiency.

DMS for Smart Workplace, Building and Meeting

LV-Tron is a DMS provider that helps businesses create smart workplaces, buildings, and meeting spaces. They specialize in designing digital solutions to streamline processes and improve productivity, leveraging technology to optimize work environments.